AUTOMATIC CBR TEST MACHINE

Automatic CBR test machine is designed for performing laboratory evaluation of the CBR value of highway sub-bases and sub-grade, and determination of the strength of cohesive materials which have maximum particle sizes less than 19 mm.

The Machine is composed of a robust and compact two column frame with adjustable upper crossbeam driven by an electromechanical ram with a maximum capacity of 50 kN and a data acquisition and processing system.

The Machine is designed to load the penetration piston into the soil sample at a constant rate to measure the applied load and piston penetration at predetermined intervals.

Two test speeds are provided 1.0 mm/min for BS and 1.27 mm/min. for ASTM/EN/AASHTO Tests. This main feature allows the user to perform tests complying to BS, EN, ASTM or AASHTO standards with the same machine.

Rapid adjustment of the platen is also provided by up and down buttons which are located on the front panel of the machine.

The Automatic Cbr Test Machine is supplied complete with;

• Depending on the body capacity, it is supplied with a 50 kN or 100 kN capacity load cell,

• Linear Potentiometric Displacement Transducer, 25 x 0.01 mm

• CBR Penetration Piston,

• PX6 Touch screen control unit,

• PX6 CBR computer software and USB connection cable.

Cbr moulds are should be ordered separately.

Advange of PX6 CBR Control Unit

• Calculates corrected CBR value at 2.5 and 5 mm.

• The digital unit saves the load value at user defined displacement values such as 0.625, 1.25, 1.875, 2.5, 3.75, 5, 7.5,10, 13 mm.

• The % CBR at 2.5 mm and % CBR at 5 mm is also automatically calculated and saved.

• Ability to perform displacement-controlled tests

• Real time display of test graph

• Multi-language support (English, French, Spanish, Turkish)

• Real-time date/time

• Test results display and memory management interface

• Closed loop PID for steady pace rate

• Connection and control feature via USB

• Free computer software for test control and enhanced report output

Technicial Features for PX6 Touch Screen

• Color TFT touch display supports 16M colors and supports 800x480 pixel screen resolution

• 3 pcs universal analog input sockets (ADC)

• Each analog input with 18 bit precision (1/256000)

• 1 replacement analog input

• Total of 4 analog high-precision measuring capacities

• 2 analog output sockets (DAC)

• PULSE / DIR outputs (PULSE / DIR / ENA) to control the servo and stepper motor drives.

• Digital outputs for general purpose (can pull relays and control different electrical units)

• Digital inputs for general purpose (receives and evaluates input signals like limit contacts from the environment)

• Potentiometer input (reference signal input for calibration and remote control)

• USB communication signal output (communicates with computers)

• Connects to local networks and the Internet with Ethernet 10/100 network connection output (optional)

• Connects to portable devices via Bluetooth wireless connection (optional)

• 500 test results can be stored in internal memory

• Due to the SD (memory) card connection, a large number of test results can be stored in the device memory (40,000 test results).

• In addition, the results can be taken from the device memory and transferred to the computer as an Excel table. (Optional)

• Resistive touch screen allows easy operation of device functions by touching the screen

• Sensor modules are compatible with loadcell (load cell), pressure sensor (4-20 / 0-20 mA), potentiometric distance sensors, strain washers, thermocouples and all kinds of mV output sensors.

• Provides precise calibration with multi-point calibration (up to 10 points)

• Setting and calibration menus are password protected and prevent unauthorized use

• Allows testing with a computer, tablet, smartphone or on the touch screen panel.

• There are many test sample information screens and test methods in the device memory and tests can be performed easily

• Different menu languages can be selected via the device via language support (Turkish, English, French, Spanish and Russian)

• Speed control algorithm is closed loop PID control and all parameters can be adjusted on user side.

• The device can switch between one-touch load and deformation control modes.

• The graphical field that visualizes the test results on the screen has the ability to change the scale automatically and automatically adjusts the optimal scale as the values change

• Firmware updates can be made via USB input. In addition, via the computer allows remote or internet update.

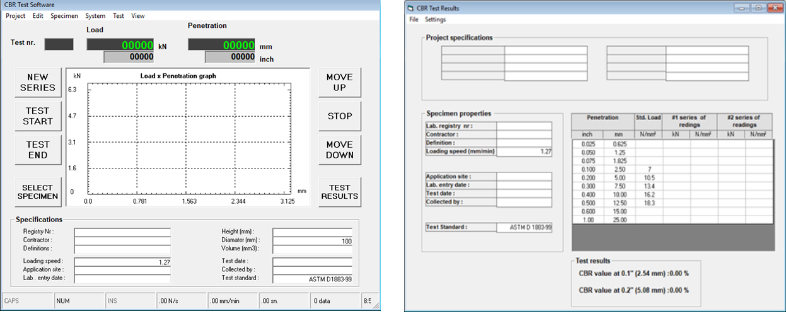

Data Acquisition & PC Software

CBR Test Software is developed for both EN 13286-47, BS 1377:4, ASTM D1883, AASHTO T193, NF P94-078 and UNI CNR 10009 standards CBR Tests.

The Cbr Software includes control of machine, acquisition of load and displacement data, saving them and reports. The Software accepts specimen diameter and height as an input parameter. It automatically calculates correction factor coming from the standarts respect to specimen size. The stability value is calculated regarding to this factor. The software continously updates load and displacement until the end of test.

When the test is completed, the sharpest slope of the graph is calculated. The point that this line crosses displacement axis is commented as an offset. This offset is subtracted from the displacement value at peak point and called as flow. Graphical outputs and reports can be saved as a MS Excel worksheet.

| Product Code | : | 54-CBR45950 | 54-CBR45960 |

|---|---|---|---|

| Capacity | : | 50 kN | 100 kN |

| Platen Speed | : | Two test speeds are provided 1.0 mm/min for BS and 1.27 mm/min. for ASTM/EN/AASHTO Tests | |

| Dimensions | : | 450x720x1100 mm | 540x740x1100 mm |

| Weight (approx) | : | 85 kg | 95 kg |

| Power | : | 370 W | 370 W |

| Product Model | Product Name |

|---|---|

| 54-CBR45950 | Automatic Cbr Test Machine 50 kN, 220-240 V 50-60 Hz |

| 54-CBR45960 | Automatic Cbr Test Machine 100 kN, 220-240 V 50-60 Hz |

Standards: EN 13286-47 | ASTM D1883 | BS 1377-4:1990 | AASHTO T193 | NF P94-078